Cart

Close

- No products in the cart.

Subtotal (excluding delivery costs)

€0,00

Repair and maintenance

Teams

Repair and maintenance

Teams

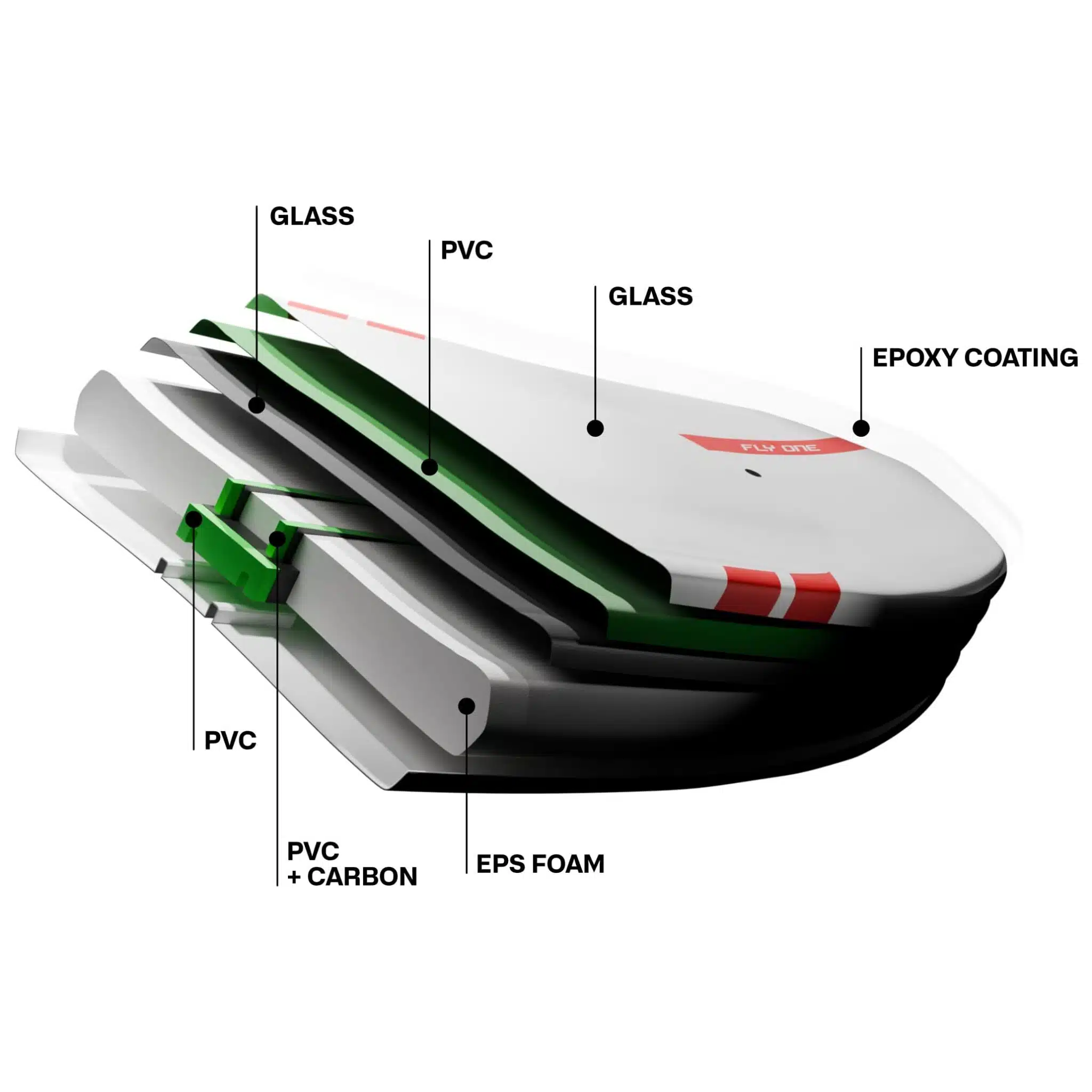

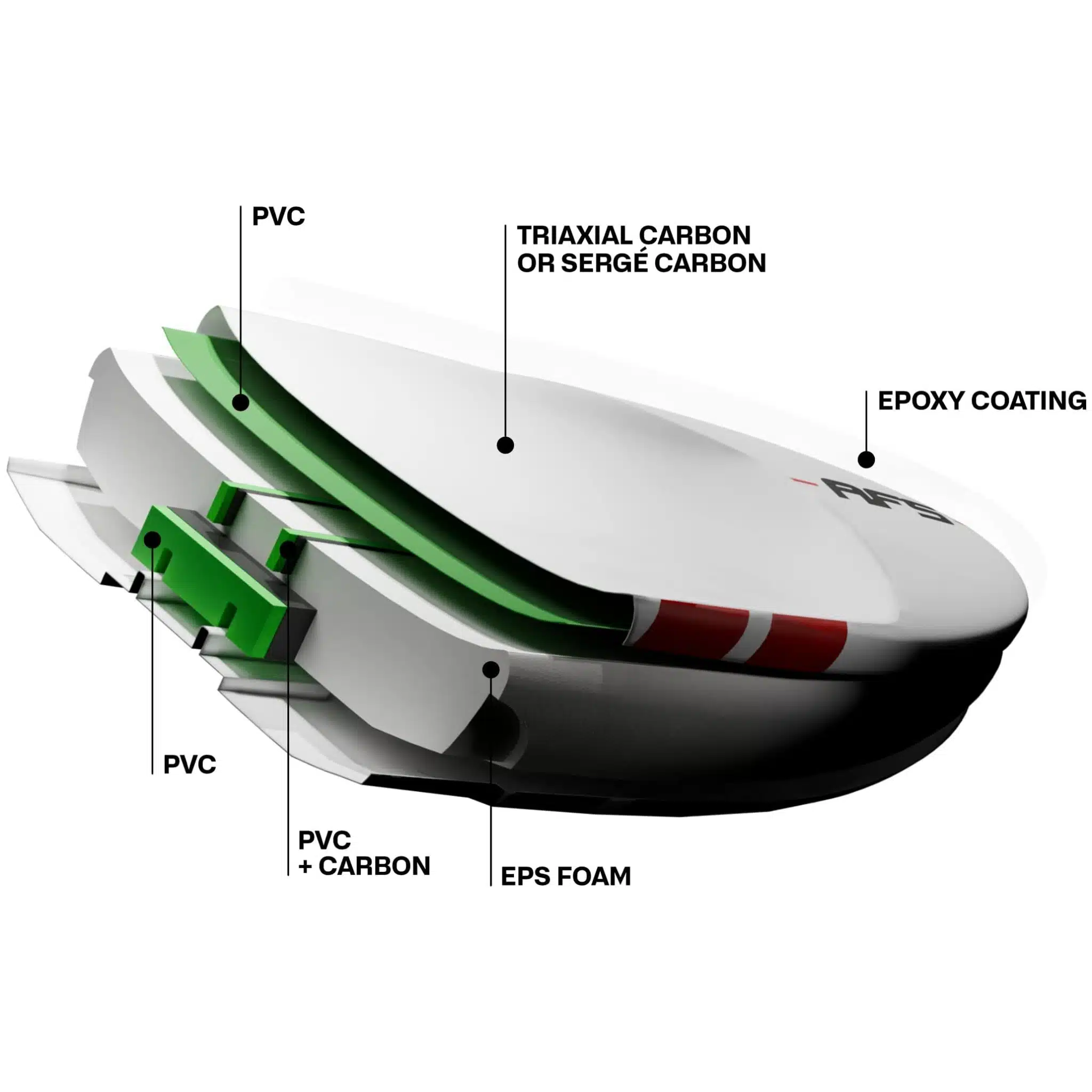

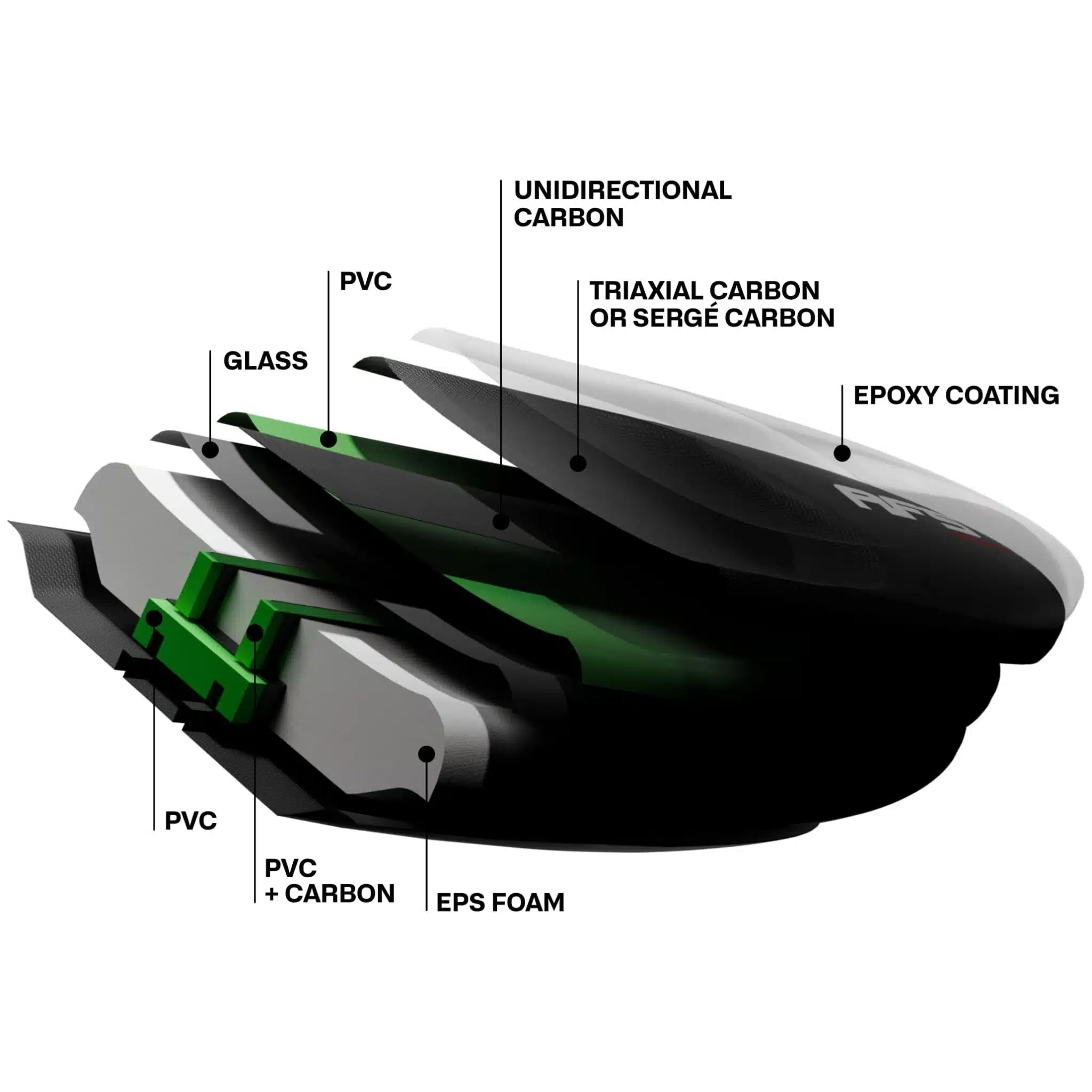

For PVC sandwich constructions, the principle is to enclose PVC sheets between multiple layers of glass or carbon to benefit from the mechanical properties of the fibers while limiting weight, thus ensuring unmatched strength. The PVC Sandwich Glass structure offers great impact and wear resistance. It is suitable for all levels of practice, from beginner to advanced. These are versatile and durable boards, offering excellent value for money.

Secure payment in 3 or 4 instalments

Advice from enthusiasts

Satisfied or refunded

2 to 3-year warranty

Europe shipping

Foil and Co., All rights are reserved. ©2024

Hello

Choose your county

The WEB team will be operating with reduced staff from Friday, August 8 to Friday, August 22. However, production and deliveries will continue as usual! For any delivery tracking requests, please write to [email protected], for billing inquiries to [email protected], and for equipment advice to [email protected].